LIMS in an Automated Workflow

Intro

A screening effort can involve testing hundreds, thousands, or even millions of molecules. Each molecule has its own unique properties and location. It’s one of these molecules that will help you make a decision to push your program forward. But how do we track the location of a molecule and its associated data? The answer to this is LIMS, which stands for Lab Information Management System. It’s not the flashiest aspect of lab automation, but it’s a crucial one for any drug discovery effort. In this post, I’ll talk about what a LIMS system is, its role in drug discovery, and describe a workflow with an integrated LIMS component.

What is LIMS

LIMS is a software component of an automated workflow that helps to track data, processes, and tasks in your lab. Here’s a video to give you an intro on this concept.

The speaker talks about three uses for LIMS systems: sample tracking, protocol execution, and storage management. These three components work together to let you know which samples are being tested in which well. This can save headaches associated with sample mixup, which can cause costly experiment repeats and back-tracking. Let’s break down these three components to understand their role in an automated workflow:

Sample tracking assigns a barcode to a sample as soon as it arrives on site and follows it through its testing and storage. We can look a little closer on how that happens when we discuss an integrated LIMS workflow

Protocol execution enhances the interoperability of an experiment so a sample is processed the same way every time. This of course is enhanced with automated liquid handling that standardizes lab techniques. Protocol execution also involves plate maps that track info like sample ID, concentration, and sample location.

Sample storage is where samples are stored for long term use. This way you’ll know where an entity is if you need to revisit it. This also tracks important information like freeze/thaw cycles, which could affect the way a sample behaves in an assay

Let’s apply these principles to a small molecule high throughput screen.

LIMS in Drug Discovery

I’m going to use small molecules in this example since I have the most experience with them. At a previous company, we outsourced our chemical synthesis to a CRO. They would arrive as a lyophilized powder in a barcoded glass vial. Here is how they would be processed:

Barcoded vials are scanned into the LIMS system by a sample management specialist

This barcode is linked to the sample metadata which contains the chemical properties like structure, molecular weight, and any associated assay data

The powder needs to be reconstituted and aliquoted, so a calculation is done based on the molecular weight and the desired concentration for how much diluent to add.

Once the calculation is done, an automated liquid handler can be used to add diluent to a vial. A worklist is used to ensure the correct amount of diluent is added to the vial.

The vials can be placed on a heat block or shaker to ensure the powder dissolves

Once all of the powder is in solution, it’s time to aliquot

Another worklist can be used with a liquid handler to distribute the aqueous compounds into vials for freezer storage.

Vials like these from micronic also have a barcode on the bottom, which can be scanned and linked to the chemical metadata.

From here, the aliquots can be stored in a freezer, with the LIMS system tracking the location in your freezer racks, or they can be given to a scientist to run an assay. Having the aliquots in 96w format also makes them easier to integrate into automated workflows.

I wanted to dive a little deeper into barcoding, since these are crucial for a LIMS system. Barcoding is used to represent data in a code using parallel lines, like with 1D barcodes, or with black and white squares, like with a 2D barcode. These codes are read with a scanner and translated into an alpha-numeric string that gives each sample its own unique ID. A LIMS system can generate a barcode for you for any additional aliquots you are making. Barcodes are important because they remove manual data entry, which is a source of error in a sample tracking workflow.

Barcoding involves picking the right barcode type for the size of your receptacle and your scanning needs. For instance, a 2D barcode will fit better on the bottom of a tube than a 1D barcode. You also need a good printer that can print your barcodes on cryo-resistant labels. Cab printers were the printer of choice for a lot of vendors at SLAS. They can integrate with a LIMS system to print the freshly generated barcodes for your use.

Scanners are also important and can range from a wireless scanner, to a flatbed scanner, to scanners that sit on the deck or inside of your liquid handlers. For scanners that sit on or in a plate reader or liquid handler, the labels need to be placed consistently on the receptacle. I’ve had issues in the past with label placement on an assay plate, where the barcode would not get read by the plate reader if the label was off center. There are two solutions for consistent label placement:

Buy consumables that are pre-barcoded

Buy a printer that automates the label placement

Let’s see how barcoding and a LIMS system are utilized in a robotic workcell designed to run assays and analyze data.

Integrated Assay Workcell

This workcell will involve software and hardware components to run a cell-based assay tracking the death phenotype to measure the efficacy of direct acting small molecules against the flu. I’m not going to specify flu strain or cell type. We want dose-response curves. The cell plates were pre-seeded, and we will just infect and treat the cells with compound. Here is the wet lab protocol:

Plate infection and treatment

Racks of de-capped compounds will be placed onto the deck of a liquid handler. Each compound has a concentration of 10mM and was dissolved in DMSO

You can automate the decapping step to save yourself a ton of time on this menial task

The dilution will start at 100uM, so a 10x plate will be generated and diluted in assay medium.

The robot will transfer 50uL of compound into 450uL of DMSO in the 10x plate

The robot will perform a serial 3-fold dilution

The robot will also add a positive and negative control from a separate plate

The liquid handler will perform the infection protocol

Barcoded cell plates will be removed from the incubator and medium containing FBS will be removed with something like the Blue Washer

Infection medium containing TPCK trypsin at a specified concentration and virus at a specified MOI will be added to the assay plate and incubated for an hour

The plate washer will remove the virus containing medium and add 45uL assay medium without FBS, but with TPCK trypsin

The liquid handler will aspirate 5uL from the 10x dilution plate and stamp it into the assay plate.

Stamping refers to a pipet head with 96 or 384 channels that can transfer the contents of from one plate to another in one step

The final DMSO concentration will be 1% in the assay

The plate will be placed into the incubator until the death phenotype is observed, which can be 24-72h based on the optimized timepoint from assay development.

Assay takedown

Barcoded plates are removed from the incubator and allowed to come to room temperature

50uL of 2X Cell titer glo is added to each well of the plate and incubated for 10 minutes at 100rpm on a shaker

Luminescence is measured on a plate reader

Data Analysis

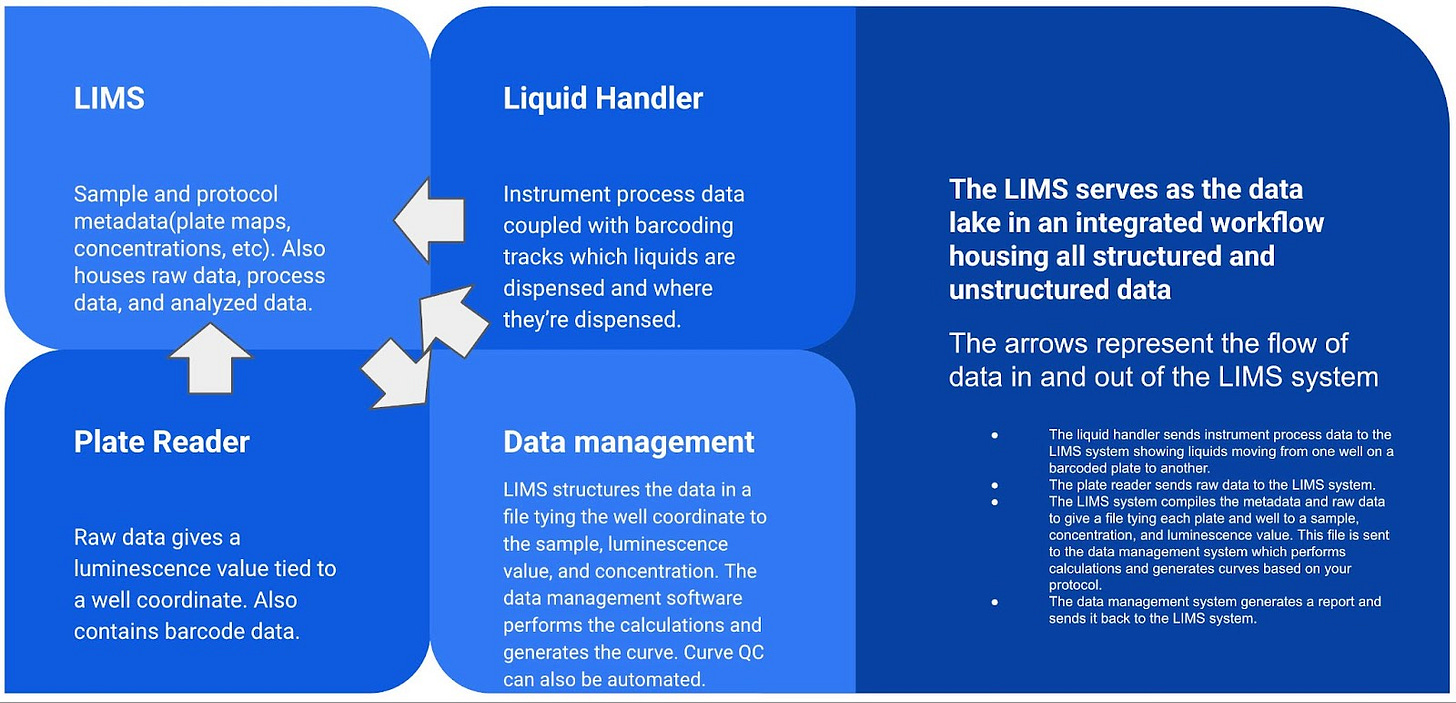

Since the data analysis is automated, I’m going to do my best to map out the data pipeline in this integrated system.

The LIMS system is crucial to automate any data analysis. I’m currently working on learning about APIs. or application programming interfaces, which is how different software applications transmit data to one another. I can get into more detail about how that works another time.

Lots of data is generated at different stages of the assay workflow, and it’s the role of the LIMS system to store and organize it all. It’s one of the keys to getting FAIR data. In a good LIMS system, you should be able to tie your sample data to assay data, and search it easily. This lets you see how a molecule performed in an assay and can make decision-making faster.

To make this work in your lab, team up with research IT, vendors, and software engineers. It takes a team to assess all of the different components of an integrated workcell. You as the scientist are there to make sure the parts make sense with your experiment.

Conclusion

A LIMS system helps you track your samples throughout their lifecycles. Along the way, it stores a ton of useful data that can be easily accessed for decisions in a drug discovery workflow. In this post, I talked about what a LIMS system is, described its role in drug discovery, and walked through an assay protocol with integrated software components.